In a rapidly evolving manufacturing sector where every minute of downtime is a deal-breaker and manual processes are considered a thing of the past, integrated packaging solutions are the new superstars of the modern production line. Whether it is bottling honey, pharma-grade filling in jars or cartoning pouches for FMCG, efficiency is not just an option anymore, it is a necessity.

Enter Nichrome Packaging Solutions: India’s packaging pioneer and eternal innovator. With our legacy spanning across 40 years, we at Nichrome have evolved from a single-product company into a global leader becoming the one stop destination with our advanced range of end-to-end automated packaging systems. We have a solution for everything—from primary packaging to secondary packaging, bottle to box and every seal, cap, and label in between.

If you own a brand, run a production team, or just love innovative entrepreneurship, this guide will be your ticket to cracking the code of the magic with our integrated packaging lines and advanced bottle filling line solution, along with our tin and jar filling systems, and secondary packaging innovations.

Why Integration is the Future (and Present) of Packaging?

Imagine an immaculately synchronized dance in which bottles move into place, are filled to the brim without a drop wasted, cap themselves, label like pros, and line up neatly into cartons — no humans needed. Such is the power of integrated packaging solutions, and this is precisely what we offer at Nichrome.

When we unite full packaging process—from filling and sealing to capping to labeling and boxing—our packaging systems guarantee:

- Streamlined operations with no bottlenecks

- Significantly minimized manual intervention

- Zero compromise on consistency; faster output

- Minimal waste of product and packaging

- Ability to be tailored to your changing needs

We see integration as a way of intelligence. We don’t just make machines—we design modular packaging systems that anticipate, collaborate, and integrate as you expand. Our design philosophy is guided by modularity, scale, and industry specificity; enabling you to automate your packaging process in stages or all at once.

Mastering Primary Packaging with Nichrome.

The foundation of every packaging operation is found in the primary packaging unit—the first contact your product makes with its protective layer. That handshake needs to be steady, hygienic and accurate.

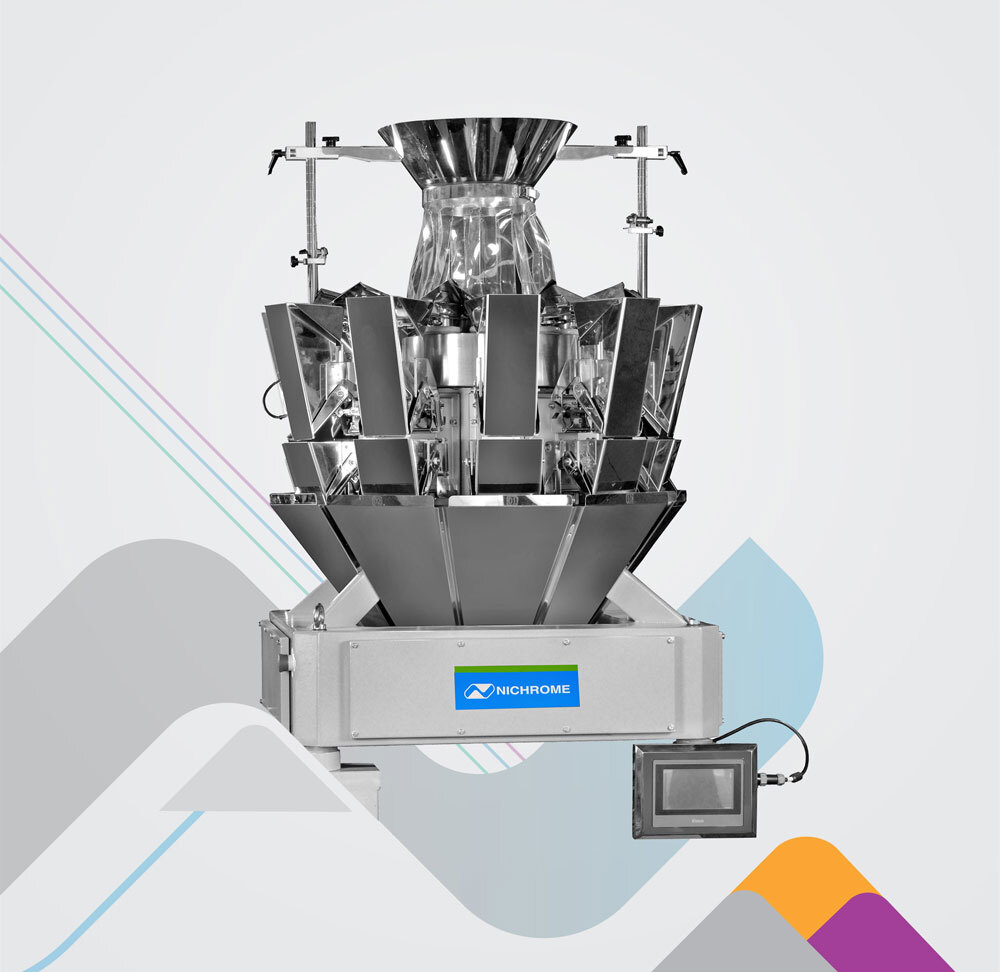

Our primary packaging solutions are designed to perform at its best in a wide range of applications. Be it liquids, powders, pastes, granules or viscous products, it can all be processed using our solutions. Being one of the topmost liquid filling machine manufacturer in India, we deliver each product with utmost precision.

We don’t do it off-the-shelf. Each automatic filling and sealing system is specifically customized to meet the needs and requirements of an industry, whether it be food and dairy, pharmaceuticals, cosmetics, or industrial chemicals. Our machines offer:

- Modular flexibility to integrate easily into your line

- Precision metering systems

- Sanitation features for easy compliance with strict hygiene norms

- Compatibility with a variety of packaging formats

Our filling machines go beyond being mere equipment — they serve as your foremost allies in ensuring quality.

Fill Bottles Like a Boss: The Nichrome End-to-End Bottle Filling Line.

When it comes to bottling, we believe in zero compromise. Our advanced bottle filling line solution are designed to cut down human errors and streamline the bottling of oils, sauces, juices, disinfectants, shampoos and even viscous medicinal formulations.

Here’s how our packaging systems are a game changer:

- Infeed turntable for smooth bottle alignment

- UV sterilization chambers to eliminate contamination

- Automatic bottle filling machines with anti-drip, anti-foam, and anti-spill tech

- Cap feeding elevators and rotary capping machines that ensure tight, tamper-proof seals

- Induction sealing stations for added protection

- High-speed labeling systems with date/batch coding

- Outfeed conveyors and packing tables that seamlessly connect to secondary packaging units

Additionally, an absolute operational safety and flexibility is guaranteed through our PLC-controlled automation, tool-less changeover and “No Bottle, No Fill” safety protocols.

If you are scaling up or diversifying your product line, our bespoke solutions scale up as you do. You get customized efficiency with no resolution sacrifice.

Tough Jobs, Smarter Machines: Filling Systems for Tin and Jar.

Some products require the use of muscle while others require absolute finesse. We have developed our tin filling and jar filling systems exactly for this.

Whatever it is you’re packaging — lubricants, edible oils, paints, or pharma-grade creams and powders — our advanced systems designed to package all of it efficiently while being robust, tough and smart. Our tin filling line consists of the following:

- Heavy duty robust design suitable for industrial surroundings

- Servo-driven volumetric filling with incredible repeatability

- Flameproof Alternatives for Volatile Products

- Safety enclosure and interlock system

- Compatible with different tin sizes (1L to 20L or more)

To offer an additional edge over others for high precision applications, our jar filling lines come with:

- Contactless, servo-controlled dispensing

- Vacuum-assisted filling for foamy or sensitive products

- Integration with capping, labeling, and laminar flow stations

- Cleanroom compliance for pharma and personal care industries

By combining precision engineering with user-centric design, we ensure your packaging process is not just smooth, but also efficient and streamlined.

Secondary Packaging with Purpose: Protection, Presentation, Perfection!

Once your product is safely filled and sealed, it’s time to suit it up for the shelf. This is where our secondary packaging solutions strut in.

These solutions are specifically designed to enhance the protection and presentation aspect for your product, while maximizing performance. From stacking to boxing and shrink wrapping to flow wrapping, our solutions include:

- Automatic Carton Box Packing Machines with integrated vision inspection, barcode reading, and rejection systems

- Horizontal Flow Wrap Machines for wrapping chocolates, biscuits, soaps, or medical devices

- Pouch stacking and bundling systems to group multiple products for retail

The integration of secondary packaging into the main line allows you to:

- Cut down manual labor drastically

- Maintain aesthetic consistency across batches

- Prevent packaging errors

- Improve traceability and compliance

The result? It’s a rugged, eye-catching, retail-ready product that performs as well on the shelf as in transit.

Benefits of Nichrome’s Integrated Packaging Systems

Let’s get down to what matter the most — what’s in it for you?

Our integrated packaging systems are not merely a set of devices connected together. They are smart packaging ecosystems that provide measurable ROI and this is how you win with Nichrome:

- Consistency and Accuracy: Every package, every time. No deviations, no surprises.

- Speed and Throughput: Reduce cycle time, meet demand spikes, and ship faster.

- Scalability: Whether you’re a startup or an MNC, our modular systems scale with your business.

- Labor Optimization: Free your workforce from repetitive tasks and redeploy them for higher-value roles.

- Compliance and Hygiene: Meet GMP, ISO, and other regulatory requirements with built-in sanitary features.

- Data and Control: Our systems come with smart control panels, analytics integration, and IoT readiness.

- After-Sales Support: Nationwide presence and proactive service teams keep your lines running smoothly.

This happens seamlessly because our solutions are customized just for you and your business’s need, not templated. With our advanced range of solutions, you can expect more than just machinery. You team up with partners who know your goals, your products, and your pain points.

Tailored for Small Businesses: Scalable Solutions, Big Impact

Even after all these amazing benefits one might think that this big orchestra of a system is only for large corporations. Well, think again! We at Nichrome build systems that are modular and scalable—perfect for small to mid-sized businesses aiming to scale smartly.

Each solution is customized to your space, volume, and budget. From compact filling lines to integrated labeling and capping modules, we make it accessible and efficient.

Our supporting components that complete the ecosystem:

- Air rinsing units for container sanitization

- Servo auger fillers for powder dosing

- Metal detectors for compliance

- Capping modules and labeling stations

- Shrink tunnels and sleeve applicators

Together, these components create a production floor that’s seamless, efficient, and future-ready.

Final Thoughts: With Nichrome, Automate Your Way to Success

At Nichrome, we do far more than just making and assembling a machine; we create the transformations. Our integrated packaging solutions help you maximize productivity, reduce costs, operation ensure consistent results and future proof your operations.

Whether you require a single automatic bottle filling machine or a fully integrated tin filling line, or stylish jar packaging systems or tough secondary packaging solutions, our technology is robust, smart and ready to perform.

You’re not just investing in a packaging system—you’re investing in agility, quality, and long-term growth. Whether you’re entering new markets, innovating a new product, or modernizing legacy systems, our integrated packaging solutions equip you to compete and win.

Reach out to us today-

We will bottle your success, cap your worries and box your future — click by click.

FAQs

Q1. What makes Nichrome’s integrated packaging solutions different from standalone machines?

Nichrome’s systems are designed to work as cohesive, modular ecosystems. They reduce manual intervention, increase speed, and improve packaging consistency across all stages.

Q2. Can Nichrome customize packaging machines for my specific product and container?

Absolutely. From the filling mechanism to capping, labeling, and secondary packaging, every solution is custom-engineered to suit your product, industry standards, and operational needs.

Q3. What industries do Nichrome’s solutions cater to?

We serve a wide range of industries including food & beverage, pharmaceuticals, personal care, agrochemicals, lubricants, and more.

Q4. How scalable are Nichrome’s packaging systems?

Very. Our systems are modular and scalable—meaning you can start with a basic setup and expand as your business grows without overhauling the entire system.

Q5. Does Nichrome offer after-sales support and training?

Yes, we offer comprehensive training, detailed SOPs, and proactive service through AMC and support teams nationwide to ensure your packaging lines run smoothly.

The post From Fill to Finish: Mastering Packaging with Nichrome’s Integrated Systems appeared first on Nichrome India Ltd.

]]>